Nalcor Energy, has announced that work on the North Spur stabilization at Muskrat Falls is proceeding as planned. “We are moving forward with the work necessary to stabilize the North Spur prior to filling the Muskrat Falls reservoir (impoundment),” said Gilbert Bennett, Vice President, Nalcor Energy Lower Churchill Project. “We have extensively studied the North Spur and the geotechnical conditions are well understood.”

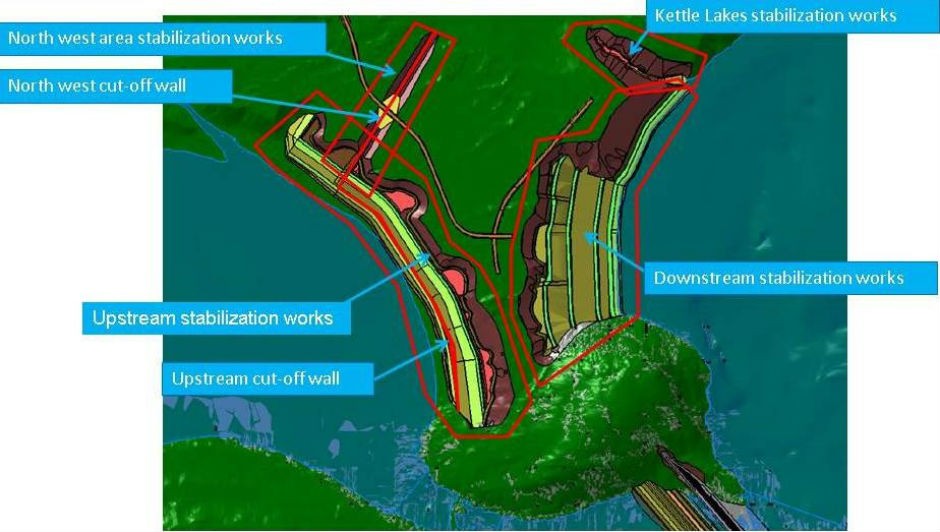

Gilbert Newfoundland and Labrador Contracting Ltd. will complete the North Spur stabilization work, including constructing cutoff walls, re-grading the upstream and downstream slopes of the North Spur, and installing erosion protection on the upstream and downstream shores of the spur.

Gilbert Newfoundland and Labrador Contracting is a division of Fernand Gilbert ltée. The company has extensive experience in overburden excavation and the construction of embankments in northern climates, equivalent to Labrador. They have experience working in northern winter climates across Canada. Recent experience includes: the construction in Quebec of embankment dams for the Eastmain and Romaine hydroelectric projects and for the Troïlus mine project; and the construction of embankment dams, including cutoff walls, for the Meadowbank project in Nunavut.

The company will open a local office in Happy Valley-Goose Bay and mobilization by the contractor to the North Spur area at Muskrat Falls and preparation for site work will begin shortly. Overall completion of the North Spur stabilization work is expected in 2017.

Background - North Spur at Muskrat Falls

The North Spur is a 1,000m long, 500m wide and 45 to 60m high ridge that connects the Muskrat Falls rock knoll to the north bank of the lower Churchill River. When the reservoir is filled (impounded) for the Muskrat Falls hydroelectric generating facility this feature will form a natural dam and become a major part of the river impoundment system.

The North Spur is composed of unconsolidated mixed sand and marine silt/clay sediments. The depth to bedrock underneath the spur is in the range of 200 to 250m. The type of clay on the North Spur is sensitive clay and the design has taken all geotechnical and other factors into account for the North Spur stabilization work.

The engineering design for stabilization of the North Spur has been undertaken by qualified geotechnical engineers, and extensive field investigations have been completed to support the engineering design. Nalcor’s project engineers and designers have incorporated special features to ensure long-term stability. These include slope modifications, the installation of a cutoff wall under the upstream slope, a drilled well system, special drainage measures and the placement protective zones to protect against erosion.

The design for the North Spur has been validated through independent reviews by the Muskrat Falls Project’s Independent Engineer as well as Hatch Ltd.

For additional technical information on the North Spur stabilization work for Muskrat Falls visit: