Advancing its commitment to maximizing customer uptime, Volvo Trucks has announced that beginning in April its Volvo Remote Diagnostics service will be expanded to monitor critical fault codes on the Volvo I-Shift automated manual transmission. Other developments related to uptime that Volvo is highlighting at the 2015 Mid-America Trucking Show in Louisville, Kentucky, include dealer investments in parts and service and the recent opening of the Uptime Center in Greensboro, North Carolina.

“Vehicle uptime is arguably the highest priority for our customers because trucks benefit their owners only if they are moving,” said Göran Nyberg, president of Volvo Trucks North America. “While technology such as Remote Diagnostics is a key element of our uptime services, we believe that a strong dealer network and knowledgeable, diligent Volvo aftermarket support personnel are critical as well.”

Remote Diagnostics, which Volvo launched in 2012 and made standard on all Volvo-powered vehicles in 2013, is a proactive diagnostic and repair planning system that monitors critical fault codes, identifies the necessary parts and supplies straightforward repair instructions to technicians, even before the truck arrives for service.

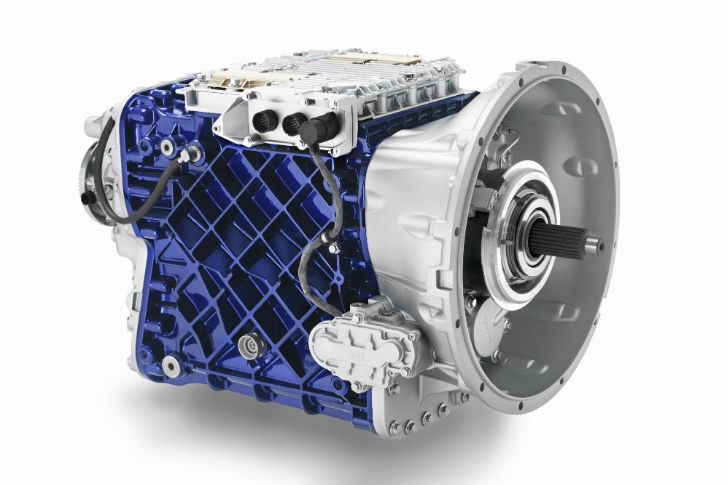

Given the success of Remote Diagnostics in proactively monitoring fault codes on Volvo engines and aftertreatment systems, beginning in April, the service will expand to monitor internal I-Shift transmission components on model year 2016 trucks. Remote Diagnostics will monitor both the standard I-Shift transmission and the I-Shift for severe-duty applications.

Uptime Center

Along with upgrading its technology, Volvo is investing in services related to uptime. The company last year opened its Uptime Center, a 123,000 square-foot facility in Greensboro, North Carolina. The Uptime Center consolidates under one roof the people and systems needed to monitor and respond to vehicle issues in real time.

Volvo Action Service agents make up the front lines of the Uptime Center, working directly with customers, dealers and Volvo representatives to resolve problems as quickly and efficiently as possible. All interaction among customers, dealers and Volvo is documented in ASIST, Volvo’s web-based service management platform, to ensure that everyone knows exactly where a case stands at any moment.

Other key members of the Uptime Center team include reliability engineers, who are responsible for diagnostics, developing service information and dealer tools and ensuring issues are addressed, and personnel focused on assisting dealers in helping the customer. Dealer support personnel troubleshoot challenging cases, manage warranty claims and resolve information technology issues. Parts specialists help dealers source parts and work with suppliers and production plants to fulfill orders.

Dealer network

Volvo Trucks dealers, which perform most of the service support required to keep trucks moving, are key to Volvo’s uptime services. Today, Volvo has more than 360 Class 8 dealer locations throughout North America, and they continue to upgrade their capabilities to maximize customer uptime.

Since 2010, Volvo dealers have invested $435 million, and many new facilities are planned or under construction. Dealer investments during this time have yielded a 37 percent increase in bay capacity, 89 percent more technicians and a 153 percent increase in the number of Volvo master technicians. Spare parts inventories are up 90 percent, and the number of parts department employees has increased 86 percent.

“Our customers have embraced our industry-leading service, Volvo Remote Diagnostics, but ultimately our skilled and dedicated aftermarket experts and dealer personnel also are integral as they help ensure their customers’ trucks are as productive as they can be,” Nyberg said.