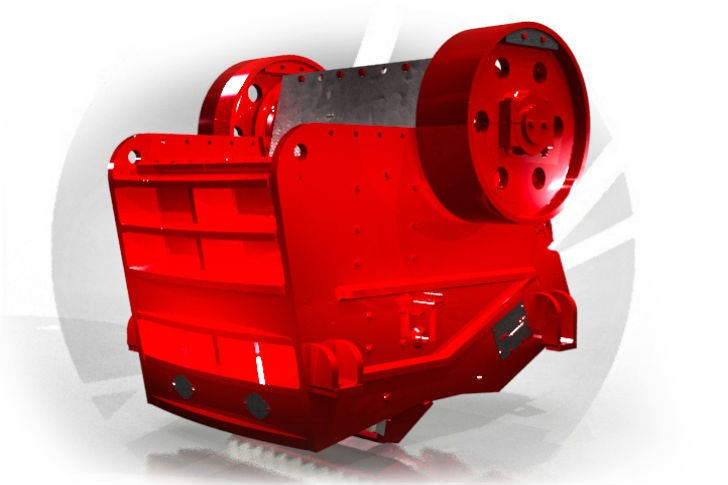

The stationary jaw die now has a bevel that rests in a matched groove on the lower clamp plate and is secured by upper clamp plates with a groove to match die bevel. Dies are also reversible.

For larger units, stationary wear plates are made of two dies with peaks in the middle and valleys on the outside. Replaceable upper and lower stationary jaw die clamp plates are lighter, making it easier to install, replace and secure the die. Clamp plates are interchangeable.

Three cheek plates per side (top, middle and bottom) allow liners in high wear areas to be replaced independently of other liners. Maintenance is greatly simplified by the inclusion of several replaceable parts, such as the barrel liner, which protects the barrel of the pitman from rock impact and scuffing, and the smash plate, which absorbs impacts, and wears and deforms before the crusher frame/pitman.

New self-aligning locking wedges are adjusted from the rear of the crusher which usually has more space for maintenance. A safety pin will lock the pitman in a closed position when maintenance is being performed.