How to minimize the effects of mismatched tires on loaders, articulated dump trucks, rigid haul trucks, motor graders, scrapers and other pneumatic-tired equipment

Tire wear results in changes to the outside diameter (OD) of each tire. As a result of this wear, tires can become mismatched (i.e. they do not have the same OD) and this can lead to accelerated tire wear and equipment damage.

Of primary importance are tires on drive axles. They must be matched for OD/circumference to avoid tire and drive train damage. Situations which can lead to tire OD mismatch are:

1. Mixing new and worn tires.

2. Mixing tires with different tread designs or tread depths on the same vehicle.

3. Mixing tires from different manufacturers on the same vehicle.

4. Mixing tires of different construction (bias/radial).

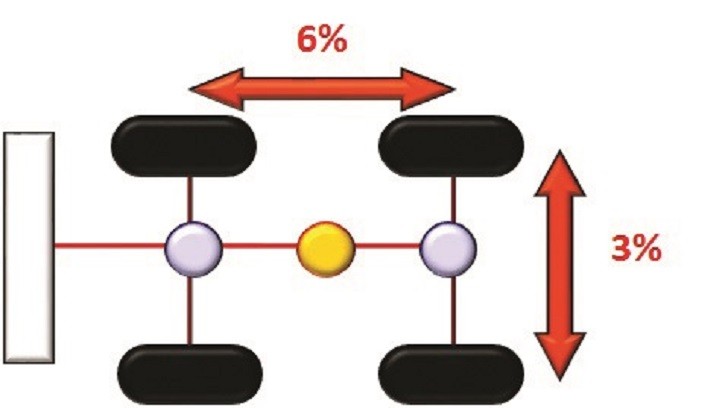

Any of the above situations can result in the mismatched tires working against each other. Consider that the drive train is designed to rotate drive tires at compatible speeds. In the situation of mismatched tires on the same axle, the smaller tire needs to rotate faster than the larger tire to cover the same distance. The drivetrain is designed to rotate the drive tires to work together, not against each other. Mismatched tire ODs/circumference will result in excess and premature tire and drivetrain wear.

Mixing new and worn tires

If all tires are matched for design and manufacturer, mounted concurrently, with the recommended inflation pressure, and have equal service time, the tread wear and resultant tire OD should remain similar and within guidelines. To maximize tread wear life and produce the most even possible wear, follow a tire rotation program prescribed by your servicing dealer or tire manufacturer.

The consequences of failure to maintain tire ODs within acceptable tolerances will result in excessive, premature tire and drivetrain wear. Mismatched tire ODs may also lead to increased fuel usage, reduced productivity and compromised vehicle handling:

Matching tire OD on duals

It is also very important to match tire OD/circumference on dual tire fitments. As with drive tire mismatching, the smaller tire needs to rotate faster than the larger tire to cover the same distance. Also, with mismatched duals, the larger tire will carry a larger portion of the load.

What results is that the larger tire will likely be overloaded and, will suffer fatigue damage and a subsequent reduction in tire life. The small tire is carrying a lighter load and is being turned too slowly to cover the same distance as the large tire therefore, the tread will be scrubbing and will wear very quickly.

As the tread wear progresses much faster on the lightly loaded smaller tire compared to the heavily loaded large tire, the difference in tire OD/circumference between the two duals grows at a more rapid pace.

This situation will destroy both tires in a short time. Your servicing dealer or tire manufacturer can help with recommendations for acceptable dual OD/circumference differences. Some manufactures publish helpful guidelines such as those in the BKT OTR Tire Maintenance Manual.

How to avoid the cost of mismatching tires

The most common occurrence leading to mismatched tire OD occurs when one tire must be removed for repair. We recommend a good tire management program. Keep an inventory of variously worn, repaired tires for replacement needs. When a tire must be removed from service for repair, use care to replace it with a tire of the same design from the same manufacturer and with similar remaining tread depth to the remaining tires on the vehicle.

We recommend you consult your equipment manufacturer for best recommendations.

Note: Comments in this article assume all tires are properly inflated for the loads applied.

Ron Tatlock is training and engineering manager at BKT USA.

Company info

55 York St., Suite 401

Toronto, ON

CA, MSJ 1R7

Website:

bkt-tires.com

Phone number:

905-641-5636