BBA Pumps introduces a new concept for high head and mining pumps

BBA Pumps has worked to develop clean and super silent mobile pump sets. This is driven in part by the stringent European emissions legislation, whereby diesel-powered equipment must comply with the Stage V requirement from 2019.

Markets outside Europe are also set for change. Countries in which environmentally sustainable solutions were traditionally of lower importance will also experience stricter emission requirements in the coming years.

Development

Last year BBA Pumps started working on a new concept for pump sets in the power range from 100 to 400 kW. In addition to the focus on the use of clean engines, flexibility to quickly and efficiently solve the needs of the user was also an important consideration.

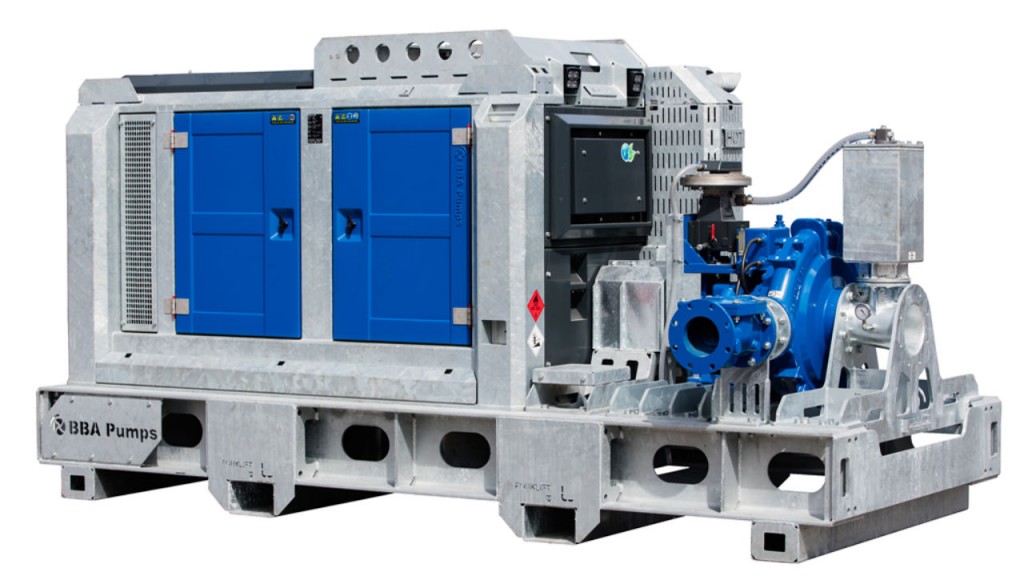

The solution was found by means of a modular construction. Through use of a modular assembly, BBA Pumps can now quickly and easily construct the desired pump set.

How does it work?

The user specifies the desired duty point, from which the correct pump module is then selected in consultation with a technical advisor from BBA Pumps. Thereafter, depending on the expected power consumption, an engine cabin "module" can be added. The engine cabin consists of a modern diesel engine including aftertreatment system, fuel and/or AdBlue tank and control panel.

As a final step, the two modules are placed on a pre-specified sub-frame and by means of cardan shaft connected to each other, following which the complete pump unit undergoes a test run.

The result

BBA Pumps is ready for the future with an extensive range of high head and mining pumps with super silent canopies. Environmental compliance goes far beyond just clean engines. The tanks are equipped with a fully bunded leak-proof bottom section and the BBA Pumps production process is in full accordance with the ISO14001 Environmental Management System.