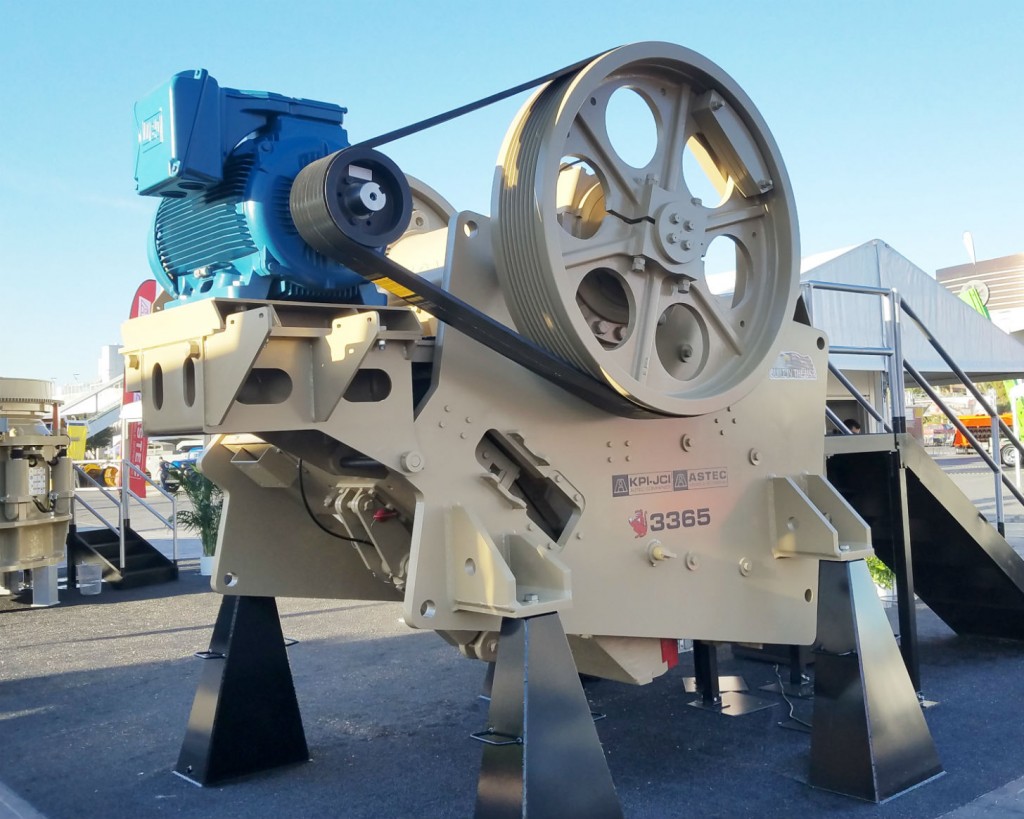

Kolberg-Pioneer, Inc. has expanded its jaw crusher product line with the new 3365 Pioneer Jaw Crusher in efforts to meet producers' operational needs.

The shaft and bearing assembly increases serviceability and reduces maintenance and rebuild cost, providing a lower total cost of ownership through the lifetime of the machine. The electric motor mount, v-belt drive and guarding are all integrated on the machine, providing an easy-to-install compact package for mobile or stationary applications.

“The 3365 is the latest introduction in Kolberg-Pioneer’s jaw crusher line,” said Tim Harms, product manager for Kolberg-Pioneer. “This crusher has up to 20 percent more capacity than the next size in its width class in both hard rock and recycled applications. The 3365 features an automatic adjust, for both the wedge style and tramp iron release systems. It also offers the advantages standard on Pioneer crushers, including replaceable jaw die seats, barrel protector plate, as well as an aggressive 1.5-inch stroke.”

The new 3365 Pioneer Jaw Crusher was released at the 2016 MINExpo, held in Las Vegas, Nev.