Volvo Penta unveils new Stage V 5- and 13-litre engines

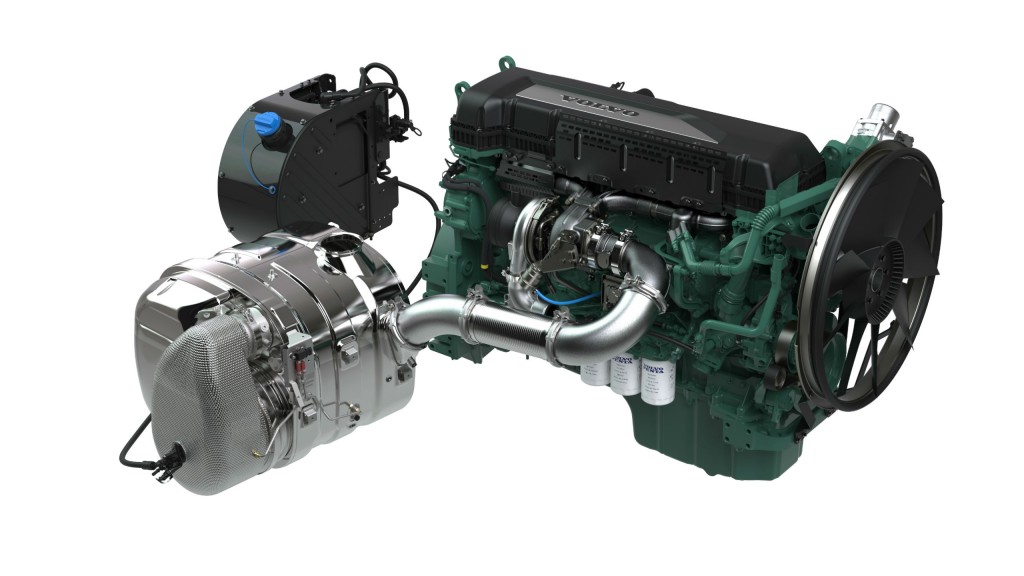

Optimized for tomorrow, the new EU Stage V engines feature the latest technology and are an ideal fit where excellent fuel efficiency, low emissions, high productivity and reliability are required. The 13-litre engine with exhaust aftertreatment system (EATS) is a great choice for large machinery while the 5-liter solution is ideal for smaller equipment.

Both are part of the full line-up of Volvo Penta's Stage V engine range - D5, D8, D11, D13 and D16, offering a power range from 105 to 565 kW (143-770 hp).

"As new emissions regulations are on the horizon for 2019, we know that OEMs are planning now on how to move towards this new chapter for equipment manufacturing," says Johan Carlsson, chief technology officer at Volvo Penta. "With our new engine solutions, OEMs can be sure that their customers will get the right power output for their needs at the appropriate emissions levels. We offer an excellent solution for manufacturers and operators, one that will also help preserve the viability of the environment."

The new 13-litre EU Stage V engine - TAD1381-1385VE - is a powerful, reliable and fuel efficient six-cylinder unit. It has a maximum output of 405 kW (551 hp) at 1900 rpm. Both are designed to deliver maximum power and torque at low rpm. This results in optimized performance, including smooth operation, low noise, and world-class fuel efficiency. Both are equipped with all the key features of Volvo Penta's Stage V concept.

The new D5 and 13 engines are compact, with hardware layout and electrical interfaces that are compatible with engines of earlier emissions legislation.

The air inlet throttle, together with the uncooled exhaust gas recirculation (EGR), and the electrical exhaust pressure governor (EPG) deliver highly effective heat management of the engine. This enables the system to function without the need to inject fuel into the exhaust stream to raise the temperature. With this approach, the exhaust gas has an optimal temperature when it passes through the EATS. Low heat rejection from the complete system means that less cooling is required.

"With our Stage V solution, the exhaust temperature is lower than the average exhaust temperatures of many competitor solutions on the market today," says Johan Carlsson. "A lower exhaust temperature can deliver big benefits to all customers, but especially those in agricultural, materials handling and forestry applications - environments where higher exhaust temperatures can have particular health and safety implications."

The new engines and complementary exhaust aftertreatment system (EATS) work in harmony to comply with forthcoming EU Stage V emissions standards. The EATS includes the following components: Diesel Oxidation Catalyst (DOC); Diesel Particulate Filter (DPF); Selective Catalytic Reduction (SCR); and Ammonia Slip Catalyst (ASC).

In addition to the 5 and 13-litre engines, Volvo Penta is also announcing an updated power output for its 8-litre Stage V engine. It has been verified through extensive testing that the TAD880-884VE delivers a power output of 250 kW (340 hp) - compared to 235 kW (320 hp) - announced earlier this year.

Volvo Penta's Stage V engines and EATS are designed to work together to maximize passive regeneration during normal operation. There is no high-temperature regeneration, because the sulfur regeneration in the SCR catalyst is not required. Only soot regeneration is needed to clean the DPF. No additional fuel injector (7th injector) for sulfur regeneration is needed. This leads to increased fuel efficiency and uptime for operators.