Tunnelling under the Fraser river

Metro Vancouver’s newest water supply project proved challenging and needed a unique mid-project – and mid-river – intervention to reach the finish line

The Greater Vancouver region boasts a population that has grown steadily over the last several decades to become Canada's third-largest urban region behind Toronto and Montreal. In 2016, there were nearly 2.3 million people residing in the area.

With population growth comes the need for services of all kinds. Water is supplied by Metro Vancouver, an overarching organization that draws water from three watersheds, treats it and moves it to the various municipalities that fall under its umbrella.

The problem that Metro Vancouver faces runs through the middle of those municipalities: the Fraser River. A large portion of the population growth has been south of the Fraser, requiring larger, newer supply tunnels to ensure everyone gets fresh, clean water. Add to those needs the concern regarding potential seismic activity, and it's no surprise that new water mains can be complicated.

Metro Vancouver's newest water supply project had to defeat all of those challenges by boring through the silty soil below the mighty Fraser and ensuring the pipes can handle significant earthquakes.

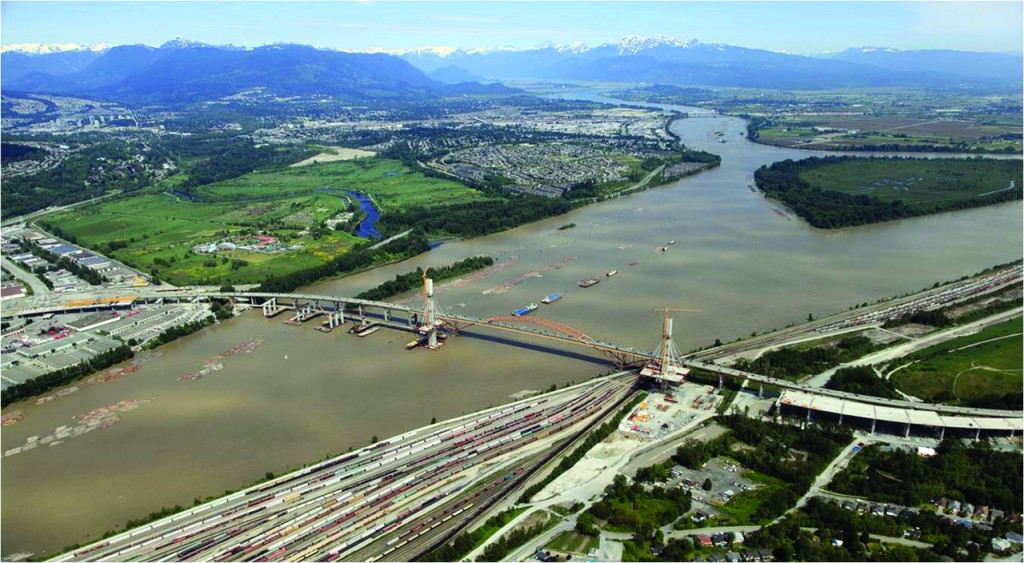

The project took place at Port Mann, near where the Trans-Canada Highway crosses the Fraser between the municipalities of Surrey and Coquitlam. Metro Vancouver has had an existing main at the site which was selected for the new crossing in the 1970s; the line actually failed in 1997 and had to be repaired using divers, according to Frank Huber, director of major projects, management systems and utility services for Metro Vancouver.

"Because of the challenging conditions under which the pipe had to be repaired - 25-foot-deep murky water - we really didn't think there would be a long life to that fix. At the time, we estimated ten to twenty years," Huber said. "That was one catalyst for doing this replacement; the other was seismic. In the late 1990s we started looking at where we were vulnerable to an earthquake and determined our most vulnerable points were the marine crossings."

Boring through difficult terrain

When models were developed to determine how best to keep the taps flowing for the most Metro Vancouver residents in the case of a major earthquake, the Port Mann crossing was determined to be a key piece of that puzzle. Therefore, the region decided to move ahead and construction started in 2011. The plan was to bore a 3.5-metre (11.5-foot) tunnel, then build a 2.5-metre (8.2-foot) water main within that bored tunnel.

The geology of the Fraser River delta doesn't make for easy construction of deep tunnels - something that became obvious as the project got underway.

"First of all, we're in soil - it's quite variable. Near the ground surface we have peat deposits and loose fill materials to get through, which was an issue for shaft construction on both sides (of the river)," Huber said. "As you get deeper, you get into granular deposits, which are under significant groundwater pressure. When you go deeper again, you get into a clay-like deposit, and then eventually a very dense glacial till."

The variability of soil types meant crews had plenty of challenges, even before they could consider the tunnelling portion of the dig. Shafts were dug down 50 metres (about 160 feet) on the south side of the Fraser and 60 metres (about 200 feet) on the north side. Tunnelling was set to take place between the shafts, some 30 metres (100 feet) below the river bottom.

Geologically, the tunnelling job only had to work through two types of soil - occasionally rocky glacial till and clay deposits. However, it had to do so in an environment where the groundwater was pressurized to about 6 bars - a significant pressure that made picking the equipment a challenge.

"We needed a specialized tunnel boring machine to construct this tunnel; we went with an earth pressure balance machine," Huber described. "An excavation chamber at the front of the machine balances the pressure against what is happening out front, allowing the machine to advance without an uncontrollable inflow of soil and groundwater."

The contractors, McNally Construction Inc. - Aecon Constructors Joint Venture, used a Caterpillar TBM for the main bore. Huber said the machine had to be versatile due to the changing conditions.

"You had a clay deposit, which is a really good tunnelling material that's relatively straightforward to get through - we made good advance rates on that, compared to the glacial till," he said. "There were large granitic boulders in there, so we had to have specialized tools on the front of the machine that would cut these very hard boulders."

Boulders become roadblocks at mid-river

The operation went relatively smoothly for most of the 1,000-metre (3,280-foot) tunnel, though some issues with the seals around the machine shell required some slowdown and maintenance work. It was when the tunnel was about 80 percent finished that a serious problem cropped up.

With about 200 metres (660 feet) remaining, the TBM encountered a number of very large boulders - more than a metre in diameter, Huber described.

"They really beat up the machine - in fact, it got to the point where some components of the machine actually broke," he said.

In most tunnel projects, such a problem would be handled by sending mechanics down the tunnel, having the repairs done, and carrying on. When the tunnel is deep below a river and filled with groundwater, however, things are a little more complicated.

"The contractor wanted to do a hyperbaric intervention - bring in equipment that allows them to pressurize the TBM to roughly the equivalent of the groundwater outside, then have divers work in that pressurized air to fix the machine," Huber said. "What they were concerned about, though, was that the divers are not TBM mechanics, so any repairs that it needed would have to be taught to these people."

With that problem in the way, the contractor team came up with a unique - and literally cool - way to get around the need for divers.

Freezing ground solves repair challenge

The water at that spot along the tunnel was only around 9 metres deep, Huber explained, so a platform was constructed above the site of the TBM, and drilling equipment brought in to bore a number of vertical holes to a point just below the bottom of the stopped machine.

"Then, they circulated liquid nitrogen through those holes to freeze the ground. That frozen ground prevented any groundwater pressure from pushing into the excavation chamber in the machine," Huber said. "Once the ground was frozen, they were able to get into the front of the machine - it took some chipping and excavating of the frozen muck, but they could then use their mechanics to do the repairs under atmospheric conditions."

The repair work was not easy, nor was it fast - in fact, the machine was stopped for around five months. The cost, though, was slightly less than had been anticipated for the hyperbaric approach, and likely finished faster as well.

"It worked very well for us in the end," Huber said.

With those delays and challenges in the construction and completion of the tunnel, the overall project did come in behind schedule by about 18 months, but Huber said a healthy contingency included during planning helped it come in under budget. The tunnel went into service in February 2017, and is expected to be serving the south side of the Fraser for the foreseeable future.

"The tunnel was designed for a 100-year life, but what we've experienced with some of our existing tunnels that were built back in the 1930s is that it's conceivable to have a 200-year life," Huber said. "But, this tunnel will not be adequate to meet all of our needs south of the Fraser, so we have another tunnelling project in the preliminary design stage right now."

That tunnel would cross the Fraser a few kilometres downstream from the Port Mann tunnel when completed. In the meantime, Metro Vancouver is adding new water mains to help handle the increased capacity on both sides of the river. On the north side, work is expected to wrap up by the end of the year. A main running from the southern end of the new tunnel to a balancing reservoir in Surrey will start construction in late 2017 or early 2018.