Manitowoc has greatly expanded its service and support offerings and featured them at bauma 2019. The company called attention to a diverse portfolio of tools and services that bolster its crane and technologies lineup.

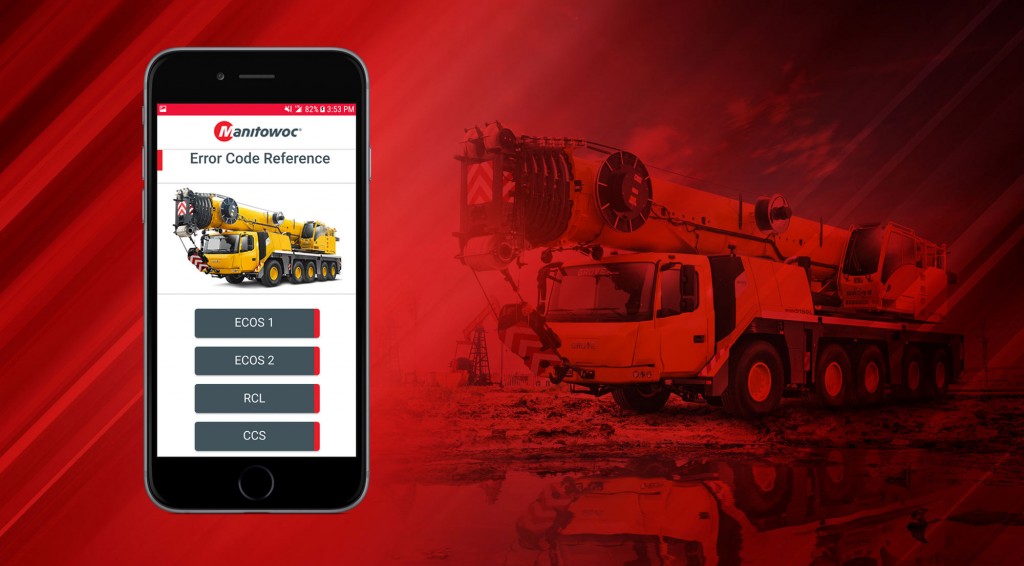

In the digital arena, the company has released two apps that help crane owners on the job site. The first is the "Manitowoc Diagnostic Code App" that helps users diagnose technical issues with their cranes. In the past, when cranes had technical issues, Manitowoc customers had no way to interpret the diagnostic codes that would appear on the main display of the crane's cab. Specialized technicians would have to be called to the job site with proprietary equipment, and any time spent waiting affected the project schedule.

Now, with this freely available smartphone app that instantly tells users what codes mean, crane owners can begin working on solutions immediately, boosting their uptime. In addition to diagnostic codes for Grove and Manitowoc branded cranes that run on Manitowoc's Crane Control System (CCS) and GMK cranes with ECOS systems, the app provides diagnostic codes for several National Crane NBT models, and for select Rated Capacity Limiter Systems on certain Grove and National Crane models.

The second app is a free "Manitowoc Boom Length Selector App" that helps crane operators and owners to quickly and easily determine the overall boom and jib length combination required for a lift. Manitowoc is the first manufacturer in the crane industry to release a smartphone app of this kind. The Manitowoc Boom Length Selector App allows users to select specific boom and jib length combinations, building heights, boom radii and other crane parameters using an easy sliding scale to determine the basic crane setup for a specific lift. Both apps are available in the Apple App Store and Google Play Store (iOS and Android).

Additionally, Manitowoc has been increasing its telematics capabilities for Potain users. With the Crane Star Diag service, tower crane customers can now access vital crane data from laptops or smartphones. This includes information relating to utilization, productivity, and fleet/crane uptime. Furthermore, crane technicians can access and upload maintenance data on cranes, and service managers can conduct real-time remote diagnostics to optimize technicians' work times and crane uptimes.

Ultimate simulation

Grove's new CCS simulator was featured during the show. The crane operator training simulator features the same CCS operating controls and displays used on newer crane models. In particular, it features a 40 t rough-terrain crane equipped with 102 ft power boom and offsettable swingaway. Six interactive job site scenarios displayed on multiple screens and a CCO practical exam course teach the operator fundamental load control skills, enabling them to gain proficiency in using CCS in a safe and controlled environment.

Grove also featured a simulator that is used for all-terrain crane training by the company's GMK Training Department. This simulator is also equipped with CCS functionality, and users of the simulator operate a virtual GMK5250 while technicians can also practice diagnostics on the virtual crane. The simulator was on hand at bauma to highlight Manitowoc's training progression program — which trains people from novice to master technician — and also includes testing and certification for master technicians. The program and its progression are unique to the industry.

Even more support

Manitowoc's long-running EnCORE program remanufactures and refurbishes cranes for customers, many of which are tied to a particular crane or feature that specifically helps their business, or for some, it's simply a way to obtain a Manitowoc crane at a lower price. Manitowoc's EnCORE program provides complete project support from consultation and refurbishment through to transportation and after-sales care.

Two additional advantages of EnCORE's refurbishment program include a 12-month warranty on the crane and its parts, plus the provision of proper technical documentation. Other refurbishment options are not able to offer the build quality, warranties or documentation that EnCORE provides. On top of that, EnCORE has some of the world's most experienced engineers dedicated to this work.

Manitowoc's booth also included a host of displays and interactive exhibits related to a range of features and services, such as its Manitowoc Crane Care customer support program and Manitowoc Finance financing arm. Manitowoc aims to provide excellent total cost of ownership for customers, and through programs such as Crane Care and Lift Solutions, the company is decreasing downtime on the job site and assisting crane operators with unique lifting plans that many modern-day applications require.

To support longevity, Crane Care showed specialist care products, a maintenance app, and also its refurbishment program for high-value components to increase the life of cranes and maximize customers' returns on investments.

"Manitowoc aims to support the lifting industry with the most comprehensive lineup of service and support options on the market," said Barry Pennypacker, president and CEO of The Manitowoc Company. "From building digital tools to expanding our training and support offerings, we want to help our customers get the most return on investment from their cranes. This is The Manitowoc Way in action."