DEUTZ presents zero-carbon alternative drive systems for off-highway sector of tomorrow

DEUTZ brought its REVOLUTIONIZING POWER - High-Performance Advanced Drive Systems to the bauma trade fair in Munich in early April. For the first time, it presented a range of innovative drive systems for zero-carbon off-highway applications of tomorrow. The international leading manufacturer of engines for the off-highway sector is now able to offer individual combinations of diesel, gas, hydrogen, hybrid and electrified drives as part of a modular product system.

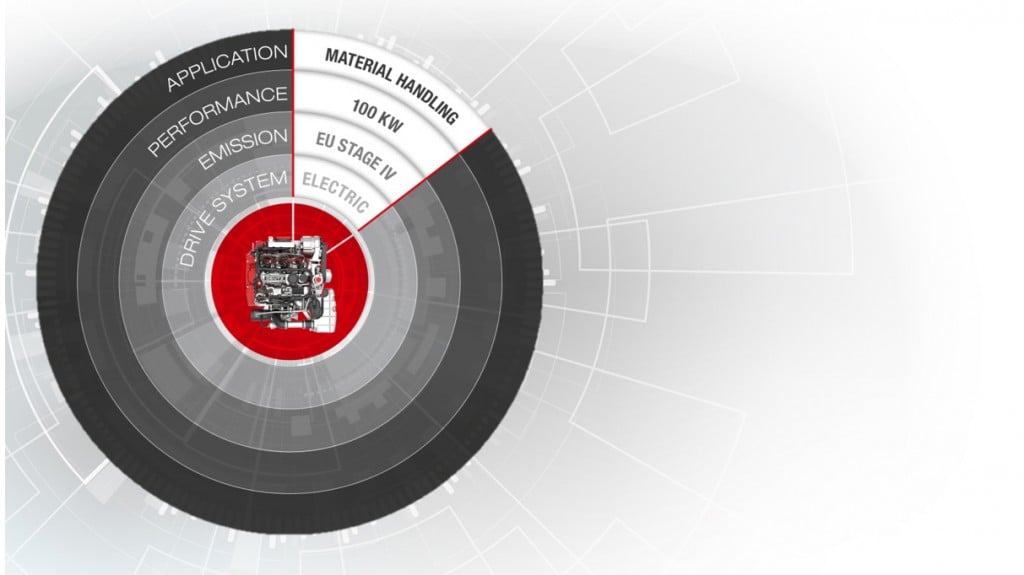

DEUTZ's modular product portfolio allows it to respond quickly and flexibly to technological advances and changing market requirements. "Our Advanced Configurator gives customers the optimum combination of conventional and electric drives," says Dr Frank Hiller, Chairman of the DEUTZ Board of Management. "Because the modular system is highly adaptable to shifts in the market, we are able to quickly supply solutions that are not only individually tailored but also reduce carbon emissions, fuel consumption and overall costs. This helps the environment and adds value for our customers."

Michael Wellenzohn, the member of the DEUTZ Board of Management with responsibility for sales, service and marketing, added: "We begin by working with our customers to define the parameters, such as performance, load profile and emissions characteristics. We then configure the optimum drive system to meet those specific requirements. The result might be a combustion engine that uses a range of fuels or it might be a hybrid or even an electric drive. We see ourselves as a development partner and systems integrator for our customers." Visitors to the trade fair were able to watch the Advanced Configurator in action in 3D shows held twice daily at the DEUTZ stand. In addition, E-DEUTZ customer applications were demonstrated in operation in the DEUTZ outdoor area.

Carbon-neutral combustion engines thanks to sustainable fuels

In addition to electrified solutions, DEUTZ's innovative drive concepts include advanced combustion engines that can run on a carbon-neutral basis by using hydrogen and other alternative fuels. Hydrogen and ‘e-fuels' (synthetic fuels based on renewable electricity) are carbon-neutral because they do not extract any new carbon and because the energy sources used are sustainable. DEUTZ has high hopes for these technologies and is presenting a hydrogen variant of its successful TCD 7.8 engine at bauma. This first prototype engine, based on state-of-the-art hydrogen technology, is the product of DEUTZ's research partnership with Munich-based start-up Keyou.

The TCD 5.2 and G 2.2 are two innovations that received their world premiere at bauma in the traditional combustion engine segment. The TCD 5.2 is a powerful four-cylinder in-line engine that will complement DEUTZ's existing diesel portfolio. Thanks to its ultra-efficient, selective catalytic reduction system, it will also be the first in-line engine from DEUTZ that complies with the EU Stage V emissions standard without the need for exhaust gas recirculation. The engine is a benchmark within its class, delivering up to 170 kW while offering extremely compact dimensions.

In the lower power output range, DEUTZ is expanding its range of combustion engines not only in terms of capacity but also in terms of the fuels they can use. The three-cylinder TCD 2.2 engine presented at bauma is based on the four-cylinder TCD 2.9. Both engines are now available as liquid petroleum gas variants - the G 2.2 and G 2.9 respectively. The G 2.2 was unveiled to the international public for the first time in Munich. Both drives will represent a further option, in particular for low-load applications in the material handling and compact construction equipment field.

DEUTZ Advanced Repair: the digitalzation of service

The DEUTZ service slogan is ‘We care. We support. We deliver'. The Company's one-stop service concept covers everything from parts fulfilment to the provision of an app and an online portal. As part of this comprehensive package, DEUTZ offers mobile engine diagnostics by smartphone and a central online platform for the rapid and efficient ordering of genuine parts. A particular highlight is the DEUTZ Advanced Repair service concept. This revolutionary augmented reality (AR) application provides mechanics equipped with tablets real-time information that helps them to carry out targeted maintenance work on DEUTZ engines, offering a foretaste of how servicing might look in the future.