MAJOR now offers the FLEX-MAT series in five styles to give producers options to improve efficiency and screening quality.

The D series is the most commonly used style of FLEX-MAT. It features single wires in the standard FLEX-MAT pattern with square openings. It is ideal for replacing square opening woven wire for precise and accurate sizing of material while improving screening capacity. The style prevents elongated material from passing through the screens and eliminates blinding and pegging. MAJOR manufactures each opening with precise 90-degree angles for maximum performance.

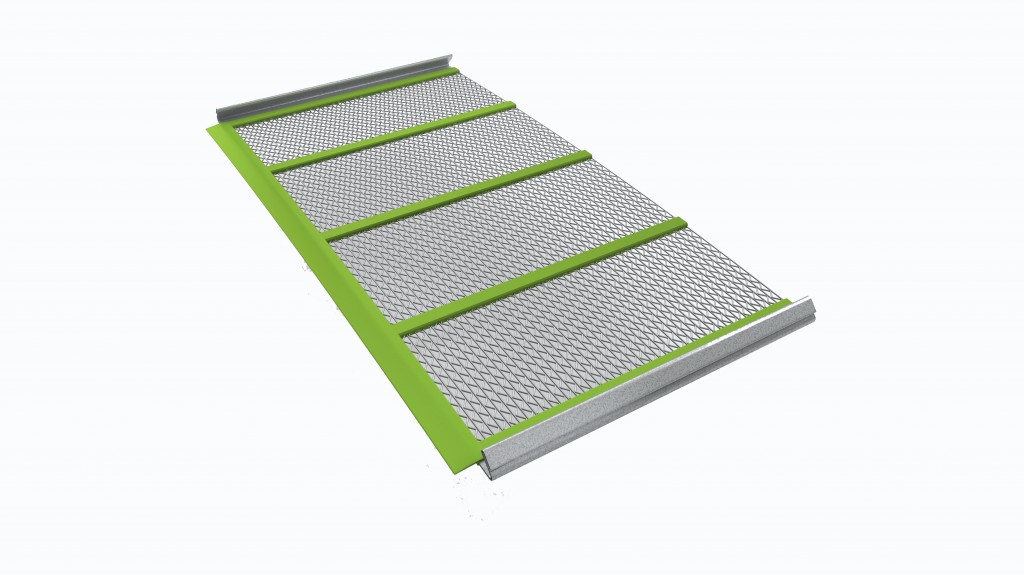

Similar to the D series, MAJOR offers the DD series for producers with high-impact, heavy-material applications who still need a large amount of open area. The style features double wires and offers durability without sacrificing productivity and screening performance, as is the case with rubber and steel plate screen media. The DD series also eliminates the "popcorn effect," which causes larger rocks bouncing higher than smaller ones on the vibrating screen, sometimes caused by single wire screen media. Operations can see as much as three times more wear life than traditional woven wire and 50% more productivity compared to steel plate and rubber panels. If installed on a machine with a proper feed pan, a 4-inch (101.6-millimeter) opening DD series setup can efficiently screen material sizes exceeding 8 inches (203.2 millimeters). DD series is available in tensioned sections, and producers can choose to add heavy-duty polyurethane strips for added durability.

The S series is ideal for low-impact and low-weight round or cubical shaped material, as well as for instances when precise passing is not required. It is also effective for sticky material. The style features an opening range from 0.059 - 2 inches (1.5 - 50.8 millimeters). The S series is recommended in applications where it is important to remove fines and output a clean product on top of the screen, or when elongated material is not a concern. The S series maximizes open area through the use of parallel wires that are not touching each other, which helps prevent blinding, pegging and lack of stratification. Material has less of an opportunity to stick to the surface because there are no holes to block. The style is available in modular and tensioned sections.

MAJOR offers the T series for fine screening with openings under 0.059 inches (1.5 millimeters). The style prevents the blinding, pegging, lack of efficiency and poor wear life seen in fine mesh. Featuring more open area than fine mesh, T series wires improve stratification and increases wear life. Producers can purchase the style in tensioned and modular sections.

The L series is available for tensioned media and is suitable for producers working in natural sand applications and with sticky materials. The style offers a variety of opening ranges, starting at as small as 0.031 inches (0.8 millimeters). The L series helps prevent blinding while also improving production rates over other types of screen media. The sections are made up of straight parallel wires that cause almost no restriction against material going through the screen.

To improve wear life, MAJOR manufactures all FLEX-MAT with polyurethane strips holding the wires together rather than the plastic strips or woven wire seen in other designs. Opening sizes stay consistent for the life of the wires because the polyurethane strips last longer than the wires.

MAJOR also offers overlaps and side seals to use in conjunction with FLEX-MAT for enhanced screening performance. Overlaps prevent material from falling between two consecutive side tensioned sections and contaminating material. Additionally, it can enhance performance by allowing material to pass from one screen to another without hitting the first wire on the second screen, increasing screen wear life. Side seals prevent oversize material from falling between the screen section and the wall of the screen box. They also improve ease of installation by allowing producers to order a narrower screen that can easily slide into the screen box. The side seals will close the gap between the walls and the screen.