ESCO develops wear cap system to help protect excavator and wheel loader bucket adapters

Working closely with customers in wheel loader and excavator applications, ESCO has identified a need for additional adapter protection.

Large quarry and small mining excavator and wheel loader working conditions can be extremely abrasive. In these conditions, top adapter wear is accelerated and shortens adapter life. The back of the tooth is exposed to more wear and impact, especially during the dumping cycle.

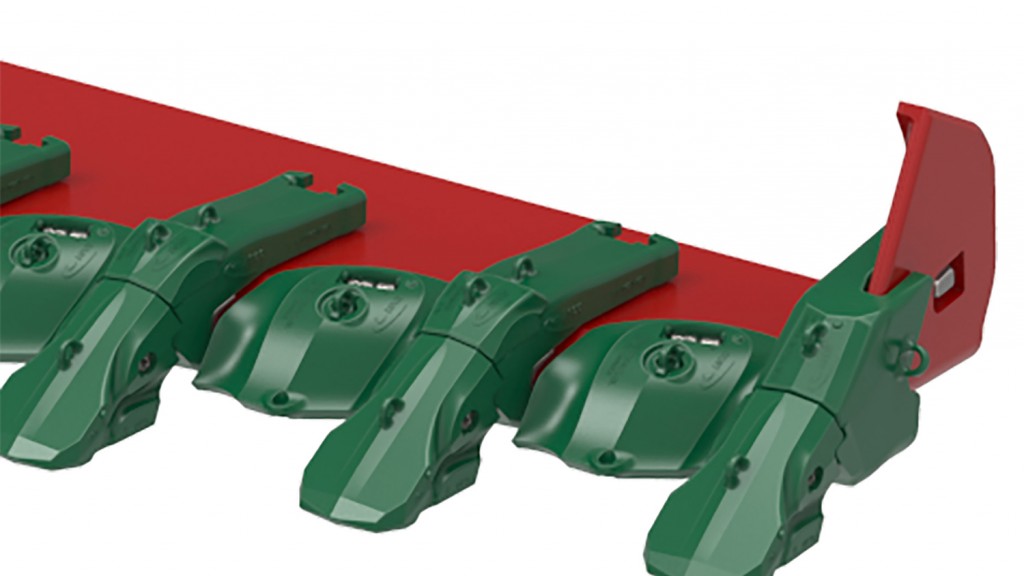

ESCO has addressed this issue with the Ultralok U60 size tooth system used in quarrying, mining, and construction applications by developing a wear cap adapter system. The wear cap adapter is now available on all U60 size wheel loaders and excavators.

The Ultralok wear cap system includes a low-profile wear cap that is held in place for quick and easy replacement. Since the wear cap is mechanically attached, it is cast in harder steel than the weld-on adapter to provide long-lasting protection.

The U60 wear cap system provides longer adapter life, more production, and lower maintenance costs to further enhance the value of the Ultralok tooth system.