Whether a repair job or a brand-new installation, road construction today requires precision and efficiency. Agencies have tight tolerances that must be met by contractors, and traditional ways of ensuring designs are correct and asphalt is properly compacted are being left behind.

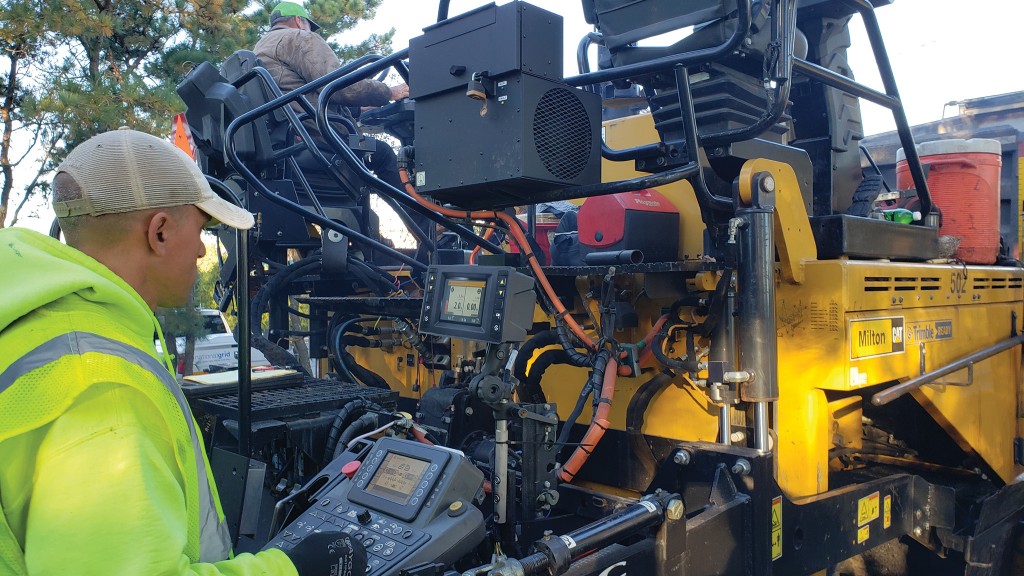

Machine control has expanded into the road construction sector, and its use is becoming more popular all the time as contractors recognize its benefits. For Trimble, that has meant development of machine control tools for a range of asphalt paving products, all providing owners and operators with new opportunities to ensure their mats have the highest quality possible.

With the recent launch of Roadworks for Asphalt Compactors, Trimble now offers a broad selection of technologies, with continuing development expected.

"Prior to that, we had Roadworks releases that supported 2D asphalt paving as well as 3D, but the most recent release introduced support for the new machine type," explained Devin Laubhan, Trimble product manager for paving solutions. "The biggest move with this platform is that we are transitioning over to our Android-based user interface platform that has been out for years in the Earthworks tools. It incorporates new software, new hardware and is a refresh . . . to modernize the solution for asphalt compactors."

While road construction requires precision, it was, for quite some time, behind in the use of technology, using manual methods for measurement and tracking of the paving process in the field. Laubhan said the advent of technology has been driven by several factors.

"We're starting to see a lot of Department of Transportation specifications around the use of 3D technologies when it comes to roadbuilding – the DOTs want to make sure the contractors building their roads are providing a quality product, and they want to make sure those roads last," he said. "3D technology can improve the building of a road from start to finish, or even a resurfacing project."

Expanding machine control in paving

Those demands have been forcing contractors to pick up machine control to some extent, but as they do the extended benefits become obvious as well, Laubhan noted. "They realize what kind of value they get from not only seeing data in real time on the screen, but how they learn from that, collect data from the site, and do post-process analysis to understand their construction workflows a little better. It helps them be a better contractor."

Technology helps contractors do better, but also aids in retention of employees in an industry that is difficult to staff, said Trimble General Manager of Civil Specialty Solutions Kevin Garcia.

"There is the very real issue of labour shortages North America-wide. The fact is that you don't have quality operators like we did in the past – there have been a lot of retirees," Garcia said. "When you're trying to ensure a brand-new operator can still do a quality job and not cost you on the back end, on your warranty or something like that, these tools can enhance that and help operators do a better job even with little to no experience."

The current trajectory for Trimble's Roadworks solutions is ensuring that 3D machine control is available across a range of paving equipment, both through OEM integration and aftermarket options.

"There are a lot of OEMs who provide factory systems that can handle the 2D part – from there, our goal is to bolt a 3D system on top of that and utilize the existing factory system," Laubhan said. "We're going to continue to move forward with additional OEM integrations for compaction . . . being able to interface with a machine ECM and get machine-specific information from the machine to Roadworks. Beyond that, we have product for milling solutions, thermal profiling, and concrete solutions that are on our road map."

Technology moves towards more autonomy

As the technology spreads, it is helping move paving equipment closer to the potential for autonomous operation – though true automation remains some distance off.

"Paving is essentially a rolling conveyor line; the process is repeated over and over again: deliver asphalt, place asphalt, compact asphalt, and move on. It lends itself well to automating portions because it is so repetitive," Garcia noted. "What we've done today is eliminate some of the operator tasks. We can't eliminate the operator altogether, but if you've ever operated a paver or compactor, there's a lot of things that you watch . . . the fewer things he has to focus on, the better a job he can do."

Roadworks can provide operators with the ability to manage truck movement and material in the auger box while the system keeps the machine steering straight and at the right speed, Garcia said, reducing operator input while improving precision.

"We can ensure asphalt is being placed at the proper depth and it doesn't require as much user intervention at the screed," he noted. "For the compaction side, you no longer have to guess how many times the roller has touched a specific section of the mix – did I roll over it four times, five times, or six times? You'll know definitively, all the time."

The ability to collect and use data from paving equipment allows owners to improve efficiency and reduce overall costs. That makes it easier to get the job done right, every time.

"Paving is known for being high stress because there isn't a backup button – you can't go ‘oh, that didn't quite finish the way I wanted it to, let me back up and do it again,'" Garcia said. "That's not an option in the paving world. I think 3D, when planned ahead of time and executed to the plan, allows for that."