First reused components successfully integrated into Scania’s assembly line

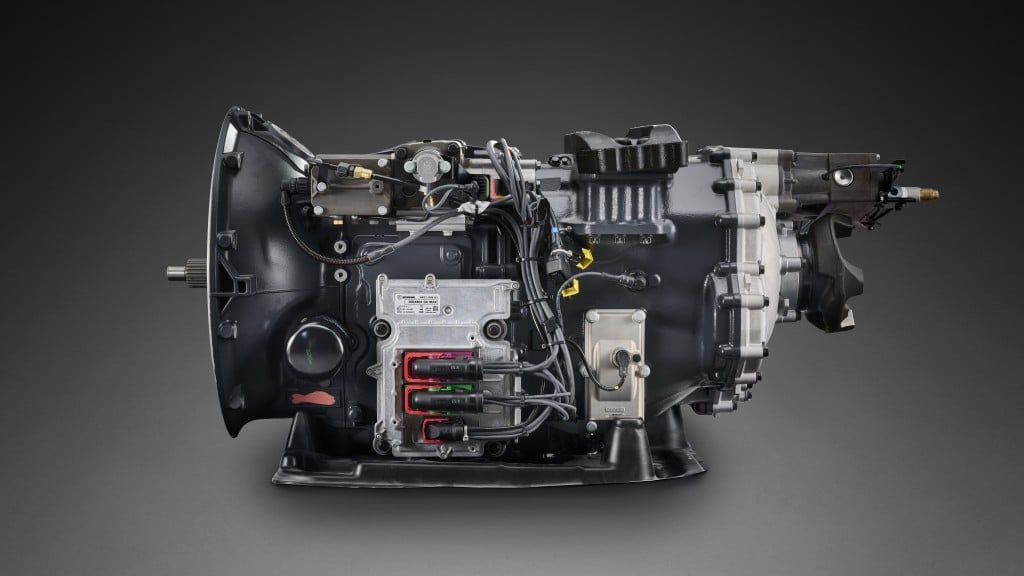

The integration of a remanufactured gearbox into a new vehicle was an industry first, and the production process showed many environmental advantages.

For the first time in the heavy vehicle industry, Scania has integrated reused components on its main assembly line in Sweden. The milestone gearbox ‘remanufacturing' project took place earlier this year as part of the iReGear joint research project with KTH Royal Institute of Technology and Scandinavian Transmission Service AB, and was made possible with funding from Vinnova, the Swedish innovation agency.

"What an achievement by the project and everyone involved. This remanufactured gearbox is a compelling example of how the manufacturing of heavy vehicles can become more sustainable, circular, and efficient, while still retaining the highest quality standards," says Fredrik Nilzén, head of sustainability at Scania.

The reused gearbox consumed about 50 percent less material and created roughly 45 percent fewer carbon emissions compared with making a brand-new one. The project shows it is possible to integrate remanufactured components directly into the production lines of new vehicles.

Same performance while consuming less material and creating less emissions

The remanufactured gearbox was subject to exactly the same rigorous steps and inline quality and function tests as gearboxes that are made from entirely new parts. It was assessed on the same test rig used for new ones, with monitoring of almost 100 quality and function parameters.

The gearbox met all those requirements and could therefore be confirmed as being "as good as new," reported the study. It meets the quality and performance standards for being installed on Scania vehicles.

As well as the remanufactured gearbox being equal to a new one in performance, the actual production process showed many environmental advantages. While replacement rates during gearbox remanufacturing can vary between roughly 10 percent to 100 percent, depending on wear-and-tear history, this particular gearbox in the project consumed approximately half of the material and caused 45 percent fewer carbon emissions compared with gearboxes made only with new components.

Remanufacturing could help the industry achieve climate goals

Remanufacturing, which is the reuse of old parts to create new products with as-good-as-new quality, can be viewed as a promising strategy for achieving climate goals and supporting the transition towards a circular economy. It also addresses increasing resource scarcity issues. In spite of its great potential, remanufacturing in the European automotive sector is mainly confined to making spare parts for aftermarkets.

The iReGear project proves use of reused parts should go further than the aftermarket

The wider adoption of the process requires vehicle manufacturers to integrate the remanufactured components directly into the production lines of new vehicles, rather than using them separately in sales to the aftermarket business. The participants hope that the pioneering iReGear project will help lead the way for the industry to make this necessary shift in the efforts to create a more sustainable and cleaner transport industry.

"STS has been remanufacturing gearboxes for more than 50 years", says Ola Stålebo, CEO of Scandinavian Transmission Service AB. "It's amazing to be able to challenge the old perception that remanufactured parts only can be used for aftermarket purposes. Today, we can proudly reflect on a period of successful collaboration, where we have achieved breakthroughs in sustainable technology. This project truly shows that it might not need to stop at just one idea, but it could become a reality in the near future."