Perkins engine compatible with renewable liquid fuels like hydrotreated vegetable oils and biodiesel

The new Perkins 2606 engine offers enhanced load acceptance, fuel efficiency, and versatility

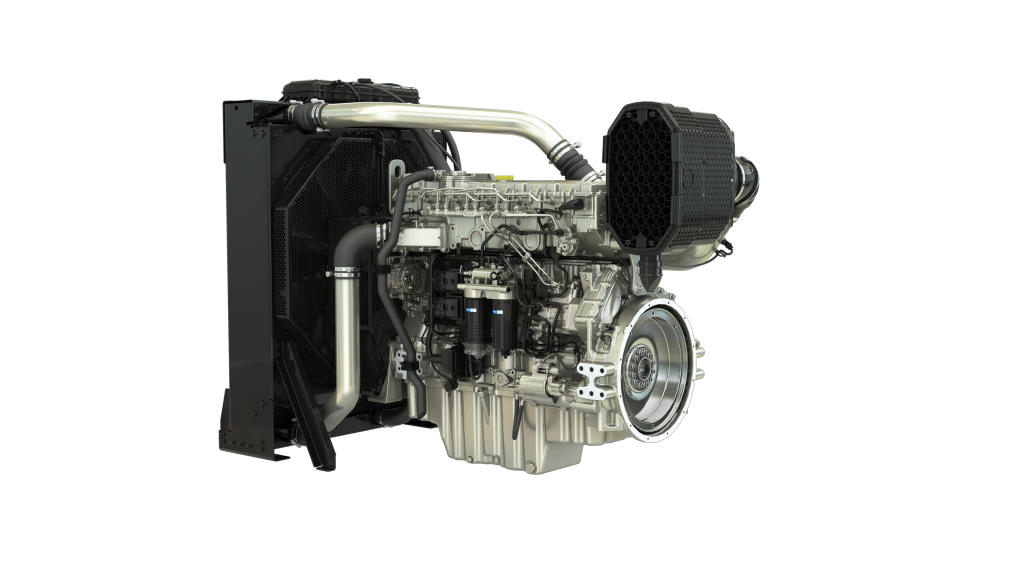

Perkins has launched the Perkins 2606 Series diesel engine optimized and purpose-built for electric power generation applications. Initially available for use in lesser and non-regulated stationary territories, this 13-litre, six-cylinder engine leverages the power density and fuel efficiency of its predecessor, the industrial Perkins 2600 Series platform.

The 2606 engine is compatible with renewable liquid fuels such as 100 percent hydrotreated vegetable oils (HVO), B100 distilled Biodiesel, and up to B100 fatty acid methyl ester (FAME) standard biodiesel.

To date, engineers have completed more than 30,000 hours of design validation and have more than 120 patents granted or pending across the entire 2600 Series engine platform. The 2606 engine for electric power is scheduled for commercial production in the second half of 2025.

Key highlights of the Perkins 2606

- The Perkins 2606 diesel-optimized engine is purpose-built for electric power generation applications.

- Delivers a powerful 321-523 kW of prime power and 365-572 kW for standby requirements.

- Easily switches between 50 and 60 Hz and across a range of voltages, enabling one generator set to satisfy requirements in diverse regions and applications.

- Adapts to the power demands of critical applications, data centres, power plants, industrial and real estate, among other installations.

- Performs at altitudes of up to 3,500 metres, and in extreme ambient temperatures as high as 60 C (140 F) and as low as minus 40 C (minus 40 F) with aids.

The engine is also suitable for power demands in prime applications, such as those found in remote worksites.

"Generator sets still remain the core foundation for stationary and mobile power generation needs across the globe, especially in places where the electrical grid is not readily available or reliable," said Jaz Gill, vice president of Perkins global sales marketing, service, and parts. "Diesel engines are still the driving force for these generator sets, so the Perkins 2606 engine takes advantage of our deep investment in the 13-litre engine platform to deliver a dynamic, versatile power plant that provides outstanding performance at low total ownership and operating costs."

Designed to reduce operating costs

The engine supports quality, reliability, and easier maintenance through numerous design enhancements, including the integration of components and a reduction in the number of leak joints by more than 45 percent. Together, the upgrades result in low fluids consumption and extended oil and fuel filter service intervals as long as 1,000 hours, reducing operating costs and downtime.

To preserve the performance and integrity of the engine whilst reducing the risk of downtime or failure, fuels must meet the specifications and characteristics described in official Perkins fluids guideline documents found on www.perkins.com. Additionally, the engine's core architecture supports the future development of spark-ignited natural gas and hydrogen fuel capabilities.