WheelJaws redefines mining tire removal safety

Kal Tire’s ground-breaking innovation protects technicians during the most dangerous part of tire removal

Founded by Tom Foord in 1953 as a small automotive service shop in Vernon, British Columbia, Kal Tire has since grown into a tire service industry leader with over 260 stores across Canada. Kal Tire's steady growth and expansion into the mining tire space since the 1970s reflects a deep commitment to innovation, safety, and performance in a rapidly evolving market.

Today, Kal Tire's Mining Tire Group delivers tire management expertise, proprietary tools, and sustainable solutions to mining industry clients across five continents. Kal Tire teams manage more than 120,000 tire changes every year. Kal Tire's growth is also measured by the creation of its forward-thinking Innovation Centre in Vernon, a hub for solutions and product design. Launched in 2015 under the leadership of Peter Nilsson, innovation and R&D manager, this centre is turning out products that enhance safety and productivity in the mining sector.

This dedication to innovation is exemplified by Kal Tire's latest breakthrough: WheelJaws, a game-changing and award-winning tire changing tool that has already gained industry acclaim. Part of the new KalPRO brand, a recently launched line highlighting the collection of Kal Tire's proprietary mining tire products and technologies, WheelJaws redefines tire management and safety practices.

The need for WheelJaws

In the heavy-duty mining and construction industries, the removal of massive earthmover tires is a high-stakes process with inherent safety risks. The standard procedure requires a tire technician to enter the narrow space between the wheel assembly and the tire manipulator to remove the final lug nuts. This step is critical yet dangerous. Human error or environmental conditions could cause the 8,000-kilogram assembly to tip, posing a severe threat to the safety of the technician.

Stories of close calls and near-misses during dismounting are not uncommon in the mining tire sector. Nilsson, an engineer with a background in food packaging, was viewing standard mining practices through the lens of a newcomer. When he visited a mining site for the first time in his new role with Kal Tire, he was shocked. "I watched a tire tech enter the space between the tire and the wheel manipulator. We call it the ‘danger area'. I thought to myself, ‘There has to be a safer way'," says Nilsson. This hazardous aspect of tire maintenance sparked the idea for a tool to help technicians work more safely and efficiently.

What makes WheelJaws unique

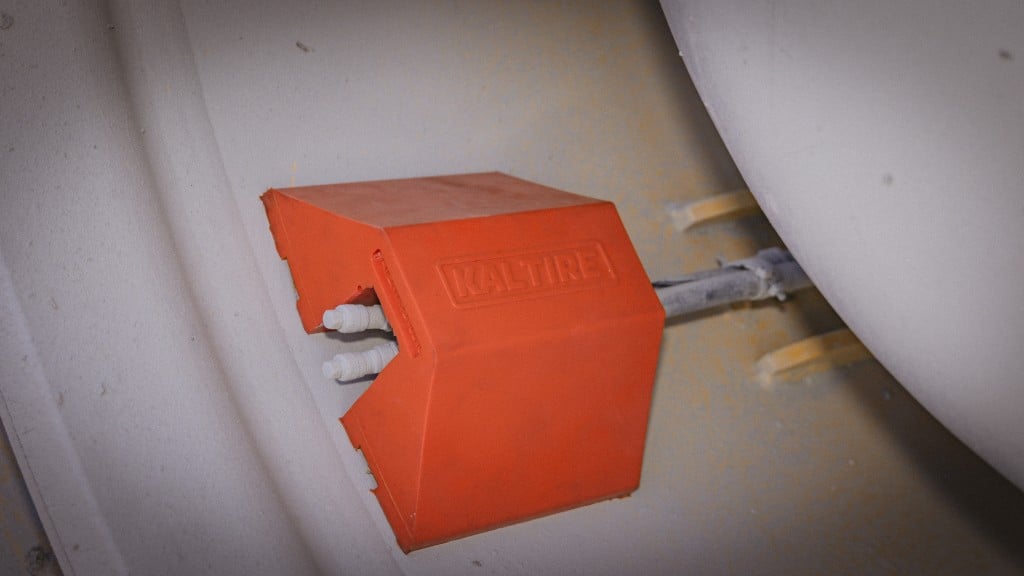

WheelJaws is a groundbreaking solution to this age-old problem in mining tire management. The core innovation of WheelJaws lies in its design and functionality. Installed at the 3 o'clock and 9 o'clock positions on the tire, the WheelJaws device secures the wheel assembly before the final lug nuts are removed. This is achieved by attaching the WheelJaws onto specific studs, effectively gripping the tire assembly in place, so that the technician no longer needs to be positioned between the assembly and the tire handler during the riskiest part of the process.

Once WheelJaws is in place, the "jaws" hold the tire securely. The device operates through a remote control, allowing the technician to engage or release the jaws from a safe distance, keeping them completely outside the danger zone. When the tire manipulator is positioned to fully detach the wheel from the vehicle, the WheelJaws remain magnetically attached until the technician can retrieve them safely.

Development journey and market impact

The development of Kal Tire's WheelJaws was a multi-year journey marked by iterative innovation and persistence. The project began with a simple concept aimed at addressing a specific safety gap in ultra-class tire handling and quickly evolved through several phases of prototyping and refinement. Early in the process, Kal Tire created a 3D-printed prototype to present to key stakeholders, sparking immediate interest and validating the need for this innovation in mining operations. However, the journey was far from straightforward.

In 2021, the team was forced to pause development due to COVID-19 restrictions, unable to test prototype number two at mine sites — a step critical to gaining real-world feedback. When restrictions lifted, the second prototype revealed significant issues that sent the team back to the drawing board. In total, Kal Tire went through four prototypes over almost three years, overcoming technical and logistical hurdles to ensure that WheelJaws would perform reliably and safely in demanding mining environments.

Innovation rewarded

As Kal Tire's WheelJaws advances safety standards in mining tire management, the product has also garnered industry recognition. WheelJaws was honoured with the International Manufacturing Innovation: New Product Award at Electra Mining Africa 2024. This prestigious award is given to top new products in the global mining sector, celebrating technological advancements that drive safety, efficiency, and innovation in mining operations.

Another KalPRO product was recognized at the Electra Mining expo in 2018. The first time Kal Tire exhibited a product at Electra, the company was awarded first prize for the KalPRO GATR, its Gravity Assist Tooling Rig for weightless tool operation.

These wins for Kal Tire have underscored the importance and the value of the company's investment in driving change through its Innovation Centre. As more organizations seek solutions that prioritize worker safety without sacrificing efficiency and performance, WheelJaws sets a new bar in tire management, reinforcing Kal Tire's ingenuity in the mining tire sector.

Market impact of WheelJaws

Market adoption of WheelJaws has been swift and global, with the first units heading to mining sites in Zambia, Australia, and Chile. This widespread demand underscores the industry's eagerness for innovations that enhance productivity and safety.

The impact of WheelJaws extends beyond safety improvements. By eliminating the most dangerous step in tire installation and removal, Kal Tire has also enhanced operational efficiency and reduced downtime. This reduction increases productivity on site but also results in substantial cost savings, especially over long-term operations where cumulative downtime can significantly affect profitability.

Key takeaways from the development process

The development journey of WheelJaws has provided Kal Tire's Innovation Centre with valuable insights that will shape future projects. One of the standout lessons learned was the importance of engaging field team members in the early stages of product development.

Through internal initiatives like the "Bright Idea" program, Kal Tire designates "Super Users" — global ambassadors in each market — who collaborate closely with on-the-ground team members to identify job site challenges and propose effective solutions. By involving those who would ultimately use and support the product at mine sites, Kal Tire secures vital buy-in, leading to a smoother acceptance of technologies like WheelJaws across its global operations.

"There is a certain pride among our team members when they feel they have a stake in a tool's development and success," says Nilsson. Recognizing this, Kal Tire sets a precedent for user-centred design and collaboration.

The future of innovation

As WheelJaws expands to more mining sites worldwide, Kal Tire is assessing the logistics of global manufacturing and distribution. Although initially produced in Canada, scaling up production to meet international demand may involve partnering with regional manufacturers in heavy manufacturing hubs. This approach could streamline distribution, reduce costs, and meet demand more efficiently as the popularity of WheelJaws grows.

Looking forward, Kal Tire's Innovation Centre is actively exploring new concepts, guided by insights gained from WheelJaws. The development process now includes regular ops meetings that gather feedback from operational teams worldwide, helping refine ideas before presenting them to leadership.

As Kal Tire considers the future, the Innovation Centre continues to be a hub for ideas and strategies that create safer, more efficient work environments for tire technicians. With numerous exciting projects on the horizon, Kal Tire is well-positioned to bring forth even more transformative solutions that prioritize safety, efficiency, and global impact. WheelJaws is a testament to Kal Tire's forward-thinking approach, one that values both innovation and the people behind it.