How live schematics improve training opportunities for heavy equipment technicians

The various systems that power and run the equipment on jobsites, at mine sites and elsewhere are always evolving - and, in most cases, growing in complexity. That makes it a challenge for the professionals who service that equipment to keep up with the changes and ensure they're ready to handle any situation that might come up.

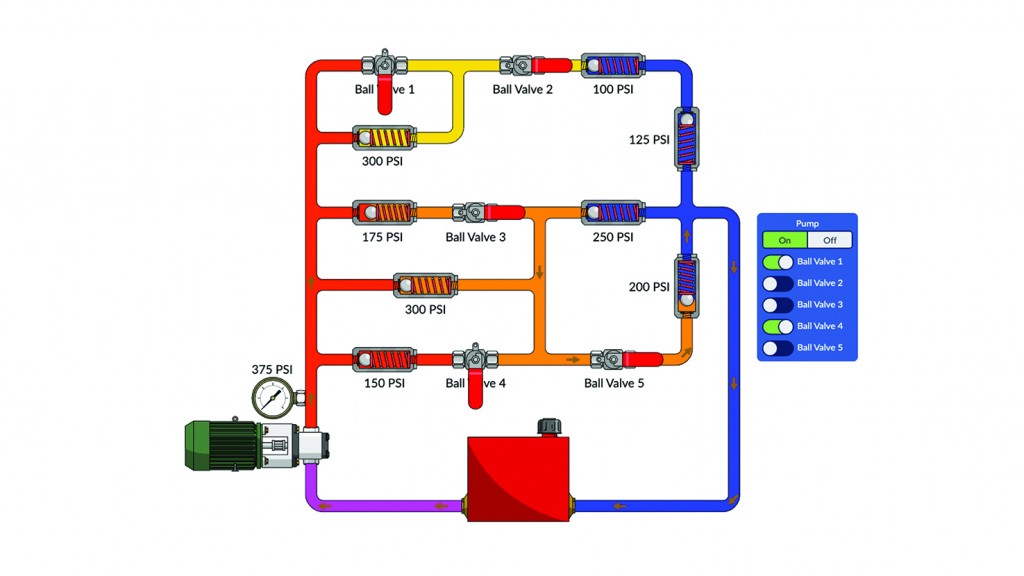

In the case of hydraulic, electrical and other systems in these machines, technicians also have to reckon with understanding those systems through the use of schematics that map out what components handle which roles, and how they all work together when active.

Paper schematics have been around for a long time, but they are static and can be difficult to track when it comes to how hydraulics or electronics operate when certain inputs take place. However, one company has taken schematics and brought them into the modern world.

"Schematics for a hydraulic system or an electrical system is a planning tool for the technician and troubleshooter. It's a way of forming a battle plan, and traditionally machines come with a manual or fold-out sheets that represent the wiring or hydraulic connections on a machine," explained Carl Dyke, CEO of CD Industrial Group. "For the most part, they're black and white – some companies put colours on the different lines, but in many of them there are so many lines and crossings and components on the page that they seem like a spider web. It's hard to bring together the relationships between one component and another just using lines."

Dyke started moving into the schematics area around two decades ago, when he realized that schematics could prove to be problematic for technicians. The growth of computer training, and later the advent of mobile computing, provided an opportunity to expand the educational potential of schematics and improve training for technicians working with these complex systems.

"Our live schematic was a tool we started developing around 20 years ago, and we've brought it through several iterations – it's now even a tablet and iPhone ready tool. What it does is brings the schematics to life as though the machine was operating – it's no longer black and white, and it's no longer static," Dyke explained.

Technicians are tasked with working on systems that are essential to the machines they are in, but that may not be very easy to understand. In many cases, they may look quite simple - but they are, in fact, quite complicated.

"Every bit of hydraulic machinery out there, or a substantial number of them, at least, have a pressure compensated pump that has to be adjusted, or at the very least have a release valve. You need to know how to adjust that correctly and safely. But, hydraulic components from the outside are just blocks of steel with hoses sticking out," Dyke said. "You can take the valve or pump apart and hold the pieces in your hand, but now it's not moving - and in some cases, some of the components just move a tiny bit. Some of the actions for certain valves are very subtle in terms of mechanical motion, but very substantial in terms of their control effect on the machine."

CD Industrial works with customers who want to give their technicians an opportunity to understand the systems of their machines more deeply, either by working with the basic schematics that come with the machine, working with the manufacturer, or by mapping out the systems on a machine themselves.

"We would send someone to the site from our team who can map out the machine, make corrections and produce a more accurate or easy to use layout – we start with the drawing, then we start to bring it to life," Dyke said.

That's done by translating the basic schematics into a computerized simulation that turns the simple line map into something far more effective, Dyke explained. Instead of a paper drawing, CD Industrial's live schematics show the system in operation, and allow the technician to see what happens when different things affect that system.

"You can see current or hydraulic flow with moving arrows, you see pressure valves as different colours, you actually see the symbols shift so if there's a switch or relay you see the contacts change position if you flip a toggle switch on the graphic or a hydraulic valve changes position," he said. "The technicians see that and say ‘now I finally get it – I understand.'"

The live schematics are not just video clips – they are provided as interactive and designed to allow technicians to try different things so they understand how inputs can affect the system, whether it's by overadjusting pressures in a hydraulic system or exploring how things react when the machine is operated too harshly.

All of this is done in a classroom situation with trainers from CD Industrial, who work with the technicians to help them better understand their equipment.

"By bringing those tools to the screen where you can see inside the system as you make changes or adjustments – or even conduct some wild experiments that might be dangerous on a real machine – you're getting some very interactive learning that fulfills the need to discover knowledge and acquire your own skills," Dyke said.

Training sessions use a variety of techniques – for example, a drag-and-drop game where photos of components on the machine are placed in the proper spots on the live schematic, or a tool that put faults into the system so the technicians must determine how to respond.

"It's all about system thinking skills and problem-solving. Technicians face some pretty tough troubleshooting projects and often a fair amount of resources are used up, perhaps time or parts that weren't necessary if there was a method to home in on a more organized and logical fashion," he said.

Training is available for a large variety of machines, ranging from stationary machines at mines or factories through mobile heavy equipment. Dyke said CD Industrial has thousands of live schematics available in its training.

The company's trainers are able to take the classroom to clients, whatever their location might be.

"We've been to the high mountains of Kyrgyzstan, the second highest gold mine in the world... we routinely go to Alaska or Texas, and sometimes to the Middle East," Dyke said. "We can travel out with trucks and trailers... the instructor goes on-site and conducts the classes. Usually the client has sent us information about their machinery and we have prepared to meet their custom needs."

Alternately, online courses can be conducted, where clients use CD Industrial materials to teach classes at their facility with what the company calls its LunchBox Sessions products.

Company info

#7 7875 48 Ave

Red Deer Alberta, AB

CA, T4P 2K1

Website:

cdiginc.com

Phone number:

1 866 628 3224